Carbide Grit Bandsaw Blade

Carbide Grit Bandsaw Blade

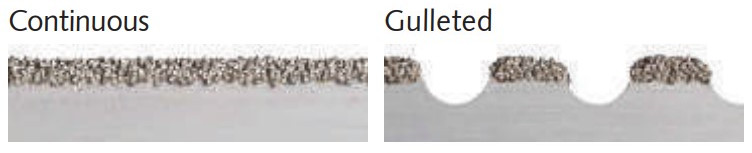

Our Carbide Grit Blades are designed to cut hard, brittle and fibrous materials. The bandsaw blades are available in “Continuous” and “Gulleted” cutting edges.

Gulleted-edge blades have grit on the cutting teeth and semicircular gaps between the teeth. They make aggressive cuts on thick materials or thick-walled pipe, cast iron, and composite materials, such as wire-embedded rubber.

Continuous-edge carbide-grit band saw blades have carbide grit on the entire length of the blade to cut thin and brittle materials, including stone, ceramic, and glass. They leave a cleaner edge and are used for less aggressive cutting than gulletted-edge blades.

Ideal for cutting

- Ceramic Tiles

- Glass

- Laminates

- Cast Iron

- Fiberglass

- Composites

- Concrete Reinforced Pipe

- Hardened Tool Steel

- Sheet Metal

- Wall Board

- Wire Reinforced Hose

- Rubber / Tyres

Carbide Grit Bandsaw Blade

0 out of 5 stars (based on 0 reviews)

Our Carbide Grit Blades are designed to cut hard, brittle and fibrous materials. The bandsaw blades are available in “Continuous” and “Gulleted” cutting edges.

-

Free Shipping

over $350 UK wide

Free Shipping

over $350 UK wide

-

Manufactured

Manufactured

in United Kingdom Purchase Direct -

100% Safety

Only Secure Payments

100% Safety

Only Secure Payments

-

UK Wide Shipping Only

LIVE: Orders Placed Today

UK Wide Shipping Only

LIVE: Orders Placed Today

| BULK DISCOUNT SAVE UP TO 15% | |

|---|---|

| QTY | DISCOUNT |

| 1 | - |

| 5+ | 10% |

| 10+ | 15% |

Technical Specifications

| Item | Carbide Grit Bandsaw Blade |

| Materials Cut | Ceramic Tiles, Glass, Laminates, Cast Iron, Fiberglass, Composites, Concrete Reinforced Pipe, Hardened Tool Steel, Sheet Metal, Wall Board, Wire Reinforced Hose |

| Cutting Edge Style | Variable |

| For Use With Saw Type | Bandsaws |

Carbide Grit Bandsaw Blade

Our Carbide Grit Blades are designed to cut hard, brittle and fibrous materials. The bandsaw blades are available in "Continuous" and "Gulleted" cutting edges.

Gulleted-edge blades have grit on the cutting teeth and semicircular gaps between the teeth. They make aggressive cuts on thick materials or thick-walled pipe, cast iron, and composite materials, such as wire-embedded rubber.

Continuous-edge carbide-grit band saw blades have carbide grit on the entire length of the blade to cut thin and brittle materials, including stone, ceramic, and glass. They leave a cleaner edge and are used for less aggressive cutting than gulletted-edge blades.

Ideal for cutting

- Ceramic Tiles

- Glass

- Laminates

- Cast Iron

- Fiberglass

- Composites

- Concrete Reinforced Pipe

- Hardened Tool Steel

- Sheet Metal

- Wall Board

- Wire Reinforced Hose

- Rubber / Tyres

As soon as your order is placed on the site, the order will be sent to the factory for processing within 12 hours of the order being received.

All orders placed before 4:00 pm UK time go into production on the following day and are dispatched the following afternoon. Unless communicated otherwise.

Please Note: Bandsaw blades under the PREMIUM CATEGORY which include "TCT Timber, Carbide Grit and Diamond Coated Bandsaw Blades can take up to 4 weeks to 3 months to be shipped due to high demand and complexity of the production process.

For Enquiries, please email [email protected] or phone +44 20 3290 8990.

- We deliver to the following locations and throughout the World.

We will arrange for the products to be delivered to the address for delivery indicated in your order. Each item will be subject to “Signed on Receipt”.

We will use reasonable endeavours to deliver products on the date for delivery set out in our order confirmation or, if no date is set out in our order confirmation, within 7 days of the date of our order confirmation. However, we cannot guarantee delivery by the relevant date.

We do however guarantee that unless there are exceptional circumstances all deliveries of products will be dispatched within 30 days of the later of receipt of payment and the date of our order confirmation

East of England

East Midlands

London

North West

North East

South West

South East

West Midlands

Yorkshire & the Humber

0 out of 5 stars (based on 0 reviews)

Write a Review

There are no reviews yet. Be the first one to write one.

Carbide Grit Bandsaw Blade

When in its monocarbide form (chemical formula of WC), tungsten carbide rivals diamond for the hardest known material. Its impact resistance, toughness, and resistance to galling/abrasions/erosions are exceptional, lasting up to 100 times longer than steel in extreme conditions.

Carbide tipped saw blades cut almost everything from asbestos to Zirconium, including paper, plastics, rubber, steel, insulation, aluminum, and even food, as well as every kind of wood in the world and all the wood composites.

Carbide Grit blades with a continuous edge are coated with thousands of carbide grains. The facets of the grains create an extreme number of cutting edges, guaranteeing an aggressive cut while still leaving a smooth surface finish.

Carbide Grit blades with a gulleted edge are still coated with carbide grains. However, the gulleted edge offers greater penetration and flexibility than the continuous edge. Additionally, bandsaws with smaller pulleys or wheels will experience longer blade life with gulleted edge bands.

For cutting materials too hard, or abrasive or thin for bi-metal blades. Tungsten carbide grains are bonded to the alloy body creating smooth cutting blades that won’t tear thin materials while offering a long life when cutting difficult materials.

Carbide remains sharper longer than plain steel, which makes makes a carbide cutting tool more efficient. Carbide enables blades to cut faster without binding, which reduces load on woodworking machines. Normal-steel cutting tools dull fast.

Carbide steel has more high cutting speed and is 4- 7 times higher than high – speed steel. Carbide is much harder, so it has a longer tool life and faster cutting data than conventional high speed steel. HSS tools also cost less than Carbide tools and are often a good solution in high-mix, low-volume applications

Select Your Blade

5 Easy Steps to Build Your Own Sawblade

Welcome to the

Sawblade.com.au

Mobile App

3. Select the Length (Round up to the Closest Increment)(Round up to the Closest Increment)

2. Now Enter the Exact Length in (mm) (Made to your Order)

Length is not correct, changed to maximum allow length.

Adjust the wheels of the machine to their correct position (about the middle of the adjustment range)

- Refering to the diagram below, measure the distance between the centre point of each wheel in mm (measurement D).

- Now measure the radius of each wheel in mm (R1 and R2).

- Use this formula to calculate the band length

3. Select the Edge Type

4. Great, Can I have your Name?

5. and your Contact Number?

6. How about your Email Address?

7. Tell us about the Project or the Exact Blade you are after.

You are Amazing!

The request has been sent to the manufacturing facility

and you will get a call within 24 business hours.

In the meantime, we have sent you an email that contains the company brochure. Looking forward to talking to you, as a blade expert will be giving you a call shortly. If it's urgent, please call +44 20 3290 8990

Showing the single result

Shipping US Wide

Shipping US Wide